Oil and Gas | Actuation |

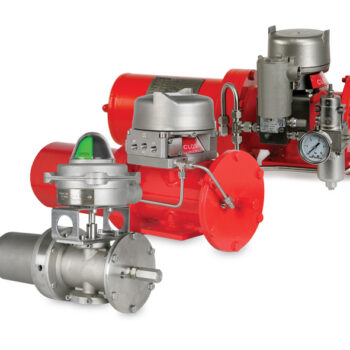

IMTEX corrosion and MAST (Maximum Allowable Stem Torque) solutions!

A customer in the North Sea gave us following challenges / problems for us to solve…

The actuators on my asset seem to corrode really quickly. Are there any Stainless Steel actuators I could use to prevent this, furthermore we are finding it really difficult to find actuation options for valves that do not exceed the valve’s Maximum Allowable Stem Torque (MAST). What options are there?

Solutions:

Part 1: The full range of Camtorc Actuators are available in both 316SS and the traditional Carbon Steel. Many operators have realised the economic sense of specifying stainless steel valve actuators as the initial small additional capital investment is recouped many times over throughout the life of an asset in

reduced maintenance and painting requirements, the removal of the need to frequently replace corroding product and, importantly, the improved reliability and safety performance for the actuated valve.

—

Part 2: Camtorc Actuators are the answer! The unique dual piston design of the Camtorc Actuator significantly reduces the potential maximum output torque from the actuator, even when all operating parameters and safety factor requirements are satisfied. This means that Camtorc Actuators, in contrast to conventional actuator solutions, do not risk damaging the valve by ‘overtorquing’ the stem. This solves a common problem experienced when sizing an actuator for a valve, particularly on MAST sensitive valves like butterfly valves and smaller bore ball valves.

Client name

Loose Ends Solutions Actuation

Solution date

2020-06-17

Solution location

North Sea - United Kingdom